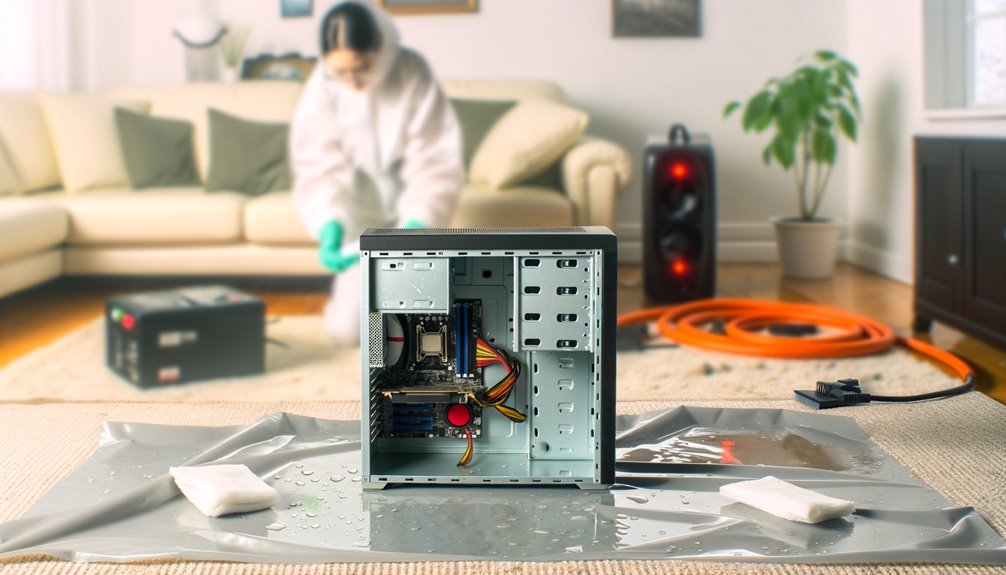

After a sprinkler pipe burst over your server rack, you’ve got minutes to prevent shock hazards and irreversible corrosion. You’ll de-energize at the panel, lockout/tagout, and suit up in insulated PPE before touching anything. Then you’ll triage by criticality and contamination, log serials, and pull batteries and power sources. Next, you’ll stage controlled drying with filtered airflow and desiccants, image storage media first, and only reapply power with current-limited supplies—if the contamination profile warrants it.

Safety Protocols Before Handling Wet Electronics

Before you approach any wet electronics, cut power at the breaker and verify circuits are de-energized with a properly rated meter. Establish isolation protocols: lockout/tagout panels, post signage, and restrict access to the affected zone. Confirm no backfeed from UPS units or generators. Don’t move equipment until you’ve stabilized the environment and documented conditions. Execute deliberate PPE selection: dielectric gloves, eye protection, waterproof boots with insulating soles, and arc-rated attire where panel work is possible. Use non-contact voltage detection first, then meter testing to ground and neutral. Control slip hazards, maintain dry footing, and stage absorbent barriers to prevent re-wetting.

Rapid Triage and Prioritization of Devices

Once the area is de-energized and stable, initiate a rapid triage to rank devices by criticality, exposure, and recoverability. Conduct an immediate inventory: identify life-safety, operational continuity, and data-bearing assets. Note power status, water type, time submerged, visible contamination, and enclosure integrity. Apply critical tagging: Red = mission-critical/time-sensitive; Amber = important/deferrable; Green = nonessential; Black = unsafe/irrecoverable. Isolate reds first, documenting serials, locations, and custody. Keep devices powered off, unplug batteries when safe, and prevent inadvertent energization. Segregate by water type and exposure level to avoid cross-contamination. Communicate priorities to stakeholders and assign clear ownership for next actions.

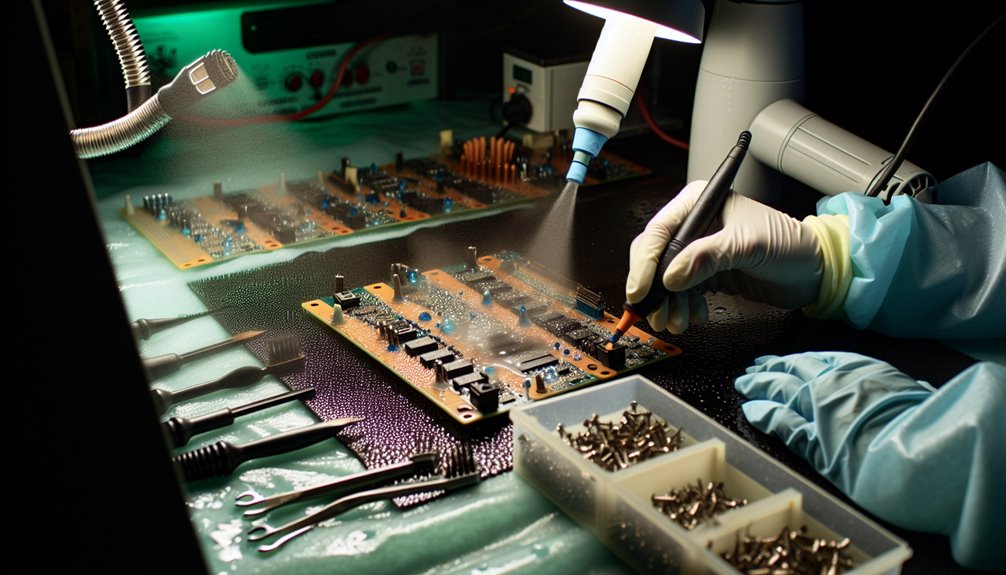

Proper Drying, Decontamination, and Corrosion Control

Although triage sets priorities, you now stabilize each device by stopping corrosion and removing contaminants before any drying heat is applied. Disconnect power, ground yourself, and remove batteries. Rinse residues with reagent-grade water or approved solvents. Displace water with isopropyl alcohol, then brush oxides with ESD-safe tools. Apply corrosion inhibitors sparingly. Use humidity mapping to set dehumidifiers and airflow. Establish moisture barriers around sensitive assemblies. Dry with controlled, cool airflow; avoid hotspots. Document component condition and contaminate sources. Prioritize worker safety and client needs.

- Gloved hands lifting a corroded PCB

- Condensation meter reading zones

- ESD mat and wrist strap

- Dehumidifier ducting tents

- Precision brush removing salts

Power-Up Procedures, Testing, and Data Preservation

Even after thorough drying and corrosion control, treat initial power-up as a controlled test to prevent latent faults from cascading. Use an isolation transformer, current-limited bench supply, and inline ammeter. Verify no-load shorts, then ramp voltage slowly while monitoring inrush and thermal rise. Disconnect nonessential peripherals.

Prioritize data: image storage media before writing to it. Use write blockers; clone to clean targets. Run post restore diagnostics: memory tests, SMART checks, and bus integrity scans. Perform firmware validation by comparing checksums and versions to trusted baselines; reflash only from authenticated sources. Log anomalies, quarantine unstable devices, and return assets safely to service.

Coordinating With Specialists and Documenting for Recovery

Before reintroducing any device to service, coordinate with certified specialists and create a defensible record. Engage restoration electronics experts, calibrate test instruments, and log chain-of-custody. Verify procedures align with manufacturer bulletins, industry standards, and safety codes. Maintain synchronized timelines for insurance coordination and legal documentation to protect clients and enable reimbursement.

- Photographs of serial plates, corrosion points, and moisture indicators

- Time-stamped videos of disassembly, drying, and reassembly steps

- Meter readings: insulation resistance, continuity, leakage current

- Signed technician reports, calibration certificates, and disposal manifests

- Cross-referenced invoices, claim numbers, and authorization emails

You’ll serve others best by proving every decision, mitigating hazards, and preserving evidentiary integrity.

Conclusion

At Hydra Clean, we understand how important your electronics and hardware are to your daily life. That’s why we treat every device with the utmost care and expertise during the water damage restoration process. If you find yourself in need of our services, I invite you to reach out and see how we can help. Visit myhydraclean.com or give us a call at (601) 336-2411. We’re here to guide you every step of the way and ensure your peace of mind. I look forward to connecting with you!